ACM-1200

ACM-1200 is an automatic vacuum capper for glass containers with twist-off caps, the ideal Packaging technology for steam incompatible products.

AUTOMATIC BLOWING MACHINE

The SF is an automatic blower for the safety cleaning of glass jars and bottles from Ø43 to Ø130, with a height of up to 260mm.

SF-M

The SF-M is a semi-automatic safety cleaning machine for glass jars and bottles from Ø43 to Ø130, up to two jars simultaneously.

VACUUM CAPPER – ACM-1200

ACM-1200 is an automatic vacuum capper for glass containers with twist-off caps, the ideal Packaging technology for steam incompatible products.

The machine is compact, versatile and customisable according to the customer’s needs, such as the extension of the incoming and/or outgoing belts or adding supports for dosing nozzles, scales and load or storage tables.

The format change is simple and allows you to adjust the machine for the use of jars and bottles from Ø43 to Ø120, with maximum height 195mm, and capsules from TO43 to TO110 both in standard and high format (DTO).

The linear transfer and the two screwing heads are driven by brushless motors that allow to reach a production rate of up to 1.200 pots/hour, ideal for small or medium productions, with adjustable clamping torque control from the the panel and reporting of any errors or anomalies.

Through the adjustment of the transfer speed to the conveyor, the linear transfer speed, the tightening torque and the desired vacuum level, it is possible to adapt the machine to every type of product, including the hot closed ones.

The rate may vary depending on the size of the jar or bottle, the product you want to pack, and the vacuum value you want to get.

The vacuum value is set on the operator panel, and is made through a mechanical pump of 45m 3 that allows a maximum vacuum of about 950mbar, controlled by a digital vacuum switch with display of the entire cycle on the panel.

If it is necessary to maintain a high level of vacuum in all productions while maintaining a high rate, it is possible to provide a pump of 63m 3 or 100m 3 positionable on a separate bench.

Optional

Additional formats

Caps pre-heating system

Technology 4.0 predisposition and compliance

Incoming and outgoing belts elongation

Rotating load/storage tables with fixed or variable speed

Dosing nozzle holder

Caratteristiche tecniche

Dimensions: 2.370mm x 970mm – height 1.860mm

Productivity up to 1.200 pots/hour

Mechanical pump of 45m 3

Adjustable values of tightening torque and vacuum level

Maximum vacuum of about 950mbar

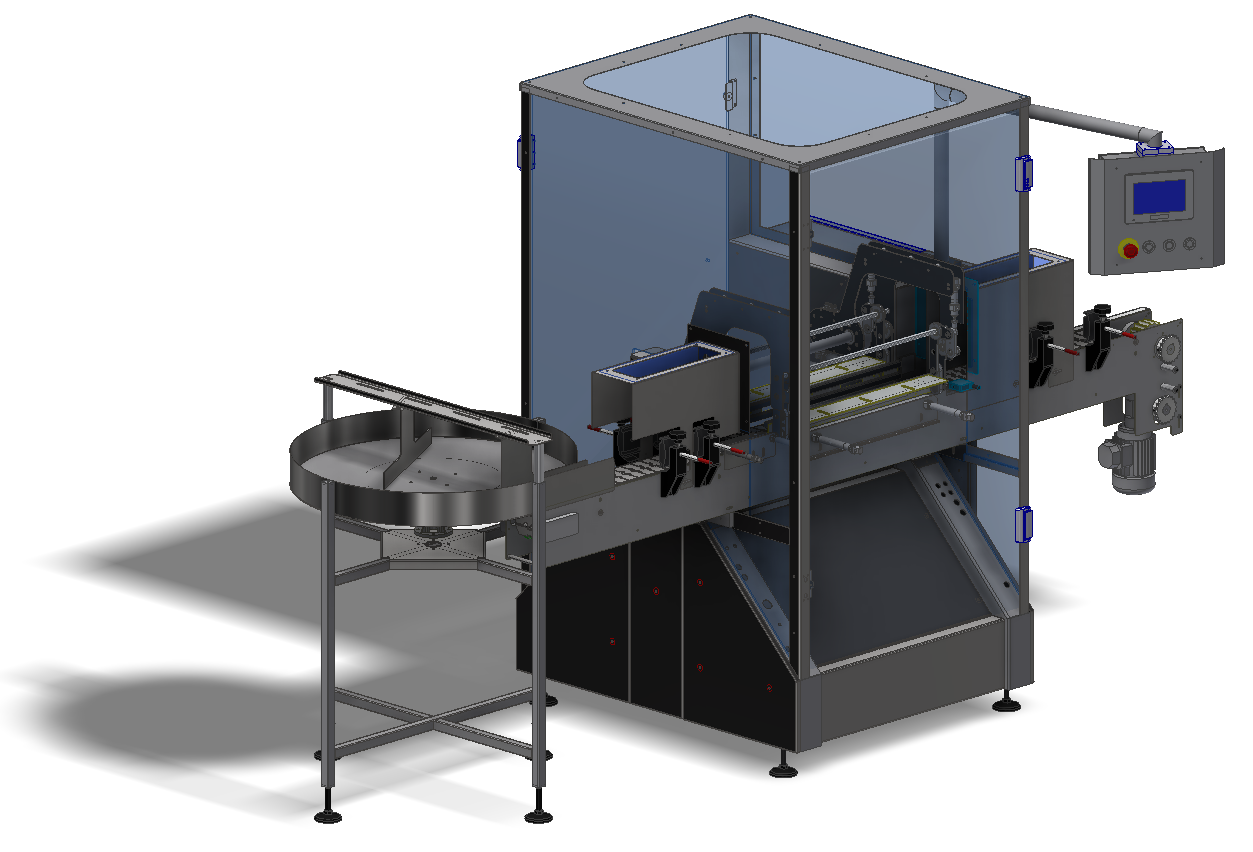

AUTOMATIC BLOWING MACHINE – SF

The SF is an automatic blower for the safety cleaning of glass jars and bottles from Ø43 to Ø130, with a height of up to 260mm.

With the blow, any dust and small debris that may remain inside the sterilized jars after storage are eliminated.

There are two alternative ways of blowing, depending on the customer’s needs: by adjustable nozzles according to the size and quantity of jars in the arm or, if the turbine is present (optional), by a micro-perforated tube without adjustments according to the jar size.

To adapt the machine to the format to be used, in addition to adjusting the blowing nozzles if present, it will be sufficient to adjust the width of the blowing arms according to the jars size.

The SF can be equipped with our inlet tables with diameters from 800mm to 1,200mm or for depalletizer machines and with supports for dosing nozzles, scales and accumulation tables at the outlet.

The blower models are made to meet different levels of production and differ in the length of the tipper arm: The SF-600 has a 600mm long arm, the SF-800 has an 800mm arm and the SF-1200 has a 1200mm arm.

Optional

Technology 4.0 predisposition and compliance

Incoming and outgoing belts elongation

Rotating load/storage tables with fixed or variable speed

Dosing nozzle holder

Caratteristiche tecniche

SF-600 Dimensions: 2.200mm x 1.130mm - height 1.810mm

Productivity with Ø60 pot:

SF-600: up to about 3.000 pz/h

SF-800: up to about 4.000 pz/h

SF-1200: up to about 6.000 pz/h

SEMIAUTOMATIC BLOWER – SF-M

The SF-M is a semi-automatic safety cleaning machine for glass jars and bottles from Ø43 to Ø130, up to two jars simultaneously.

With the blow, any dust and small debris that may remain inside the sterilized jars after storage are eliminated.

For blowing, filtered compressed air is used with purifier with 0,01µm retention degree. The blowing pressure is adjusted manually by the inlet regulator.

The manual blower is the ideal solution for small productions that still need a safety cleaning before proceeding to the packaging of the products.

Dimensioni:

500x420mm

Height 90-100cm adjustable

Maximum vessel Ø130