TSA

The TSA is an automatic welding machine for the packaging of products in preformed trays, with a welding area of

380 x 270mm.

BUCKET LINE

The bucket line is a complete line for the packaging of products in plastic buckets, adjustable according to the format

used.

TRAY SEALER – TSA

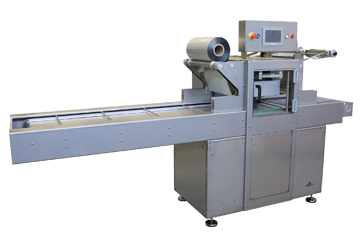

The TSA is an automatic welding machine for the packaging of products in preformed trays, equipped with a movement system and mould closing with brushless motors, that improve productivity and reduce consumption and noise compared to the pneumatic system.

The brushless motors allow greater precision in the movement of the chain and higher welding quality, as well as greater reliability.

Machine applications range from simple welding to vacuum, up to packaging in modified atmosphere (MAP) and skin.

The colour touch-screen and intuitive interface ensure that the machine can be adjusted and operated quickly and intuitively, even for less skilled staff.

It is possible to add different levels of access, which can be activated through a dedicated login, to allow only authorized staff to change certain parameters .

The machine is designed to offer the user maximum ease of use, maintenance and cleaning.

The welding area of the TSA is 380 x 270mm, with a mould depth of 100/140 mm according to the required model.

Optional

Print centering system

Tray destacker with vertical storage

Dosing nozzle holder

Separate station for Lid destacker with with pneumatic closing system

Technical features

Dimensions: 3.000mm x 1.050mm - height 1.590mm

Chain and mould movement with brushless motors

Welding area 380 x 270mm, mould depth 100/140mm

BUCKET LINE

The buckets line is a complete packaging line for the packaging of products in buckets, adjustable according to the size used.

The line is tailor-made according to the customer’s needs, and usually consists of a bucket unpacking unit, dosing or product loading area with customizable supports for doser’s nozzles or scales, lids unpacking and placement unit with closing station.

You can also insert a welding station or vacuum system with gas injection.

The line is built entirely of stainless steel and anodized aluminum, and the operator interface is simple and intuitive to allow a quick setup of the machine.

The brushless motor used for the movement of the chain allows to transport even buckets of great dimensions in a quick and fluid way.