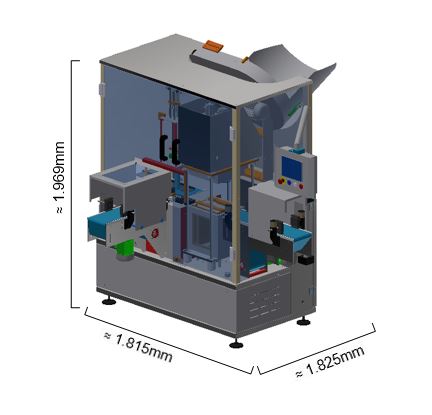

The AV-1200 is a compact and versatile double-head capping machine that can be customized according to the customer’s needs

Designed for jars and glass bottles with TO capsules, it adapts to many sizes and jar shapes up to the TO110 cap, with quick format changes. The cap is tightened through brushless motors and the vacuum is created with a 45m3 pump is controlled by analogic valve.

All the parameters related to the jar movement, the cap tightening and the percentage of vacuum are adjustable by the 7’’ touch-screen operator panel. Productivity up to 1200pcs/h.

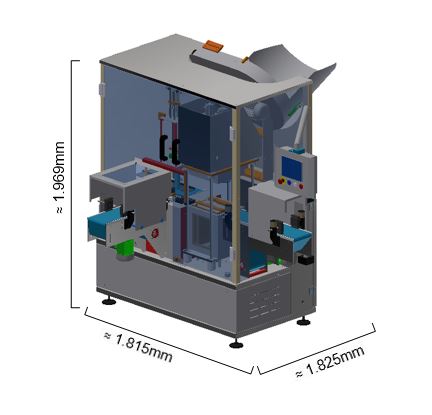

The AV-1200 is a compact and versatile double-head capping machine that can be customized according to the customer’s needs

Designed for jars and glass bottles with TO capsules, it adapts to many sizes and jar shapes up to the TO110 cap, with quick format changes. The cap is tightened through brushless motors and the vacuum is created with a 45m3 pump is controlled by analogic valve.

All the parameters related to the jar movement, the cap tightening and the percentage of vacuum are adjustable by the 7’’ touch-screen operator panel. Productivity up to 1200pcs/h.

Optional:

Additional formats

Loading or accumulation table

Additional ribbons

Optional:

Additional formats

Loading or accumulation table

Additional ribbons

Automatic blower for glass pots

The automatic blower for pots and bottles is made entirely of AISI 304 stainless steel and anodized aluminum, with lexan protections and safety sensors.

The blowing is carried out by nozzles adjustable according to the size and quantity of vessels in the arm, or by micro-perforated tube if the turbine is present (optional).

We have three automatic blower models, distinguishable according to the length of the tilting arm: the SF-600 has a

600mm long arm, the SF-800 has an 800mm arm and the SF-1200 has a 1200mm arm.

Production:

SF-600: up to about 3.000 pcs/h with Ø60 pot

SF-800: up to about 4.000 pcs/h with Ø60 pot

SF-1200: up to about 6.000 pcs/h with Ø60 pot

The automatic blower for pots and bottles is made entirely of AISI 304 stainless steel and anodized aluminum, with lexan protections and safety sensors.

The blowing is carried out by nozzles adjustable according to the size and quantity of vessels in the arm, or by micro perforated tube if the turbine is present (optional).

We have three automatic blower models, distinguishable according to the length of the tilting arm: the SF-600 has a

600mm long arm, the SF-800 has an 800mm arm and the SF-1200 has a 1200mm arm.

Production:

SF-600: up to about 3.000 pcs/h with Ø60 pot

SF-800: up to about 4.000 pcs/h with Ø60 pot

SF-1200: up to about 6.000 pcs/h with Ø60 pot

Optional:

Loading table at the entrance

Additional ribbon

Blowing by turbine

Dosing nozzle support

Opzionali:

Loading table at the entrance

Additional ribbon

Blowing by turbine

Dosing nozzle support

SF-M manual blower

The SF-M manual blower is a manual pot cleaning system with 0.1μ air filtration for 2 pots at a time, ideal for small productions.

The standard size for the passage is Ø120 to allow the cleaning of the most common pot and bottle sizes.

Size:

500x420mm

Height 90-100cm adjustable

Maximum vessel Ø130

The SF-M manual blower is a manual pot cleaning system with 0.1μ air filtration for 2 pots at a time, ideal for small productions.

The standard size for the passage is Ø120 to allow the cleaning of the most common pot and bottle sizes.

Size:

500x420mm

Height 90-100cm adjustable

Maximum vessel Ø130